Olga Ozhogina is a Ukrainian place reporter, journalist and photojournalist. She contributed this report to House.com’s Qualified Voices: Op-Ed & Insights by means of the press heart at Promin Aerospace, a Ukrainian rocket startup.

Even with the activities unfolding in Ukraine, Ukrainian providers keep on to work and create house systems. Promin Aerospace is just one these types of corporation conquering the unparalleled disruption to usual existence.

Promin Aerospace has verified its thought over the previous few months of a one of a kind self-burning rocket, an idea dependent on autophagic, or “self-devouring,” technology. The corporation has now executed the initial a few experiments on the motor for its launch auto strategy, which has permitted for advancements to the style and design as properly as confirmed the viability of the central idea.

Connected: Ukraine strategies to be a part of the EU. Will the nation’s house prospective buyers broaden as a outcome?

Reside updates: Russia’s Ukraine invasion and room impacts

Promin Aerospace co-founder and CTO Vitaly Yemets proposed the main of the company’s autophagic technological know-how, which incorporates a hull consisting of reliable gasoline propellant for a single-stage rocket. The rocket burns by itself up or “consumes by itself” almost solely all through the duration of the flight, leaving next to no particles in place. Additionally, the rocket gets a lot more successful as it climbs, consuming alone and minimizing its mass.

The progress of the autophagic motor is the initially phase in creating a comprehensive launch automobile that considers the concerns of each area particles and rocket-portion re-entry. These problems are starting to be far more prevalent as much more rocket corporations become operational. Promin Aerospace’s engineers are at the moment conducting a lot more assessments on the engine to make improvements to the style and start off do the job on the next phase of the autophagic rocket idea.

“Many thanks to this sequence of experiments, we figured out what can be finished much better in the style of the motor and nozzle,” Yemets stated. “As a result, we improved the velocity of gasification with a new gasifier printed on a 3D printer, proved the performance of the new oxidizer and eliminated burnouts.”

It would be unachievable to make these improvements to the motor if the engineers didn’t experience inside issues on every action of tests these problems gave clarity on what precisely in the building design ought to be upgraded or adjusted. Beneath is a summary of just about every specialized test executed prior to and all through the recent invasion.

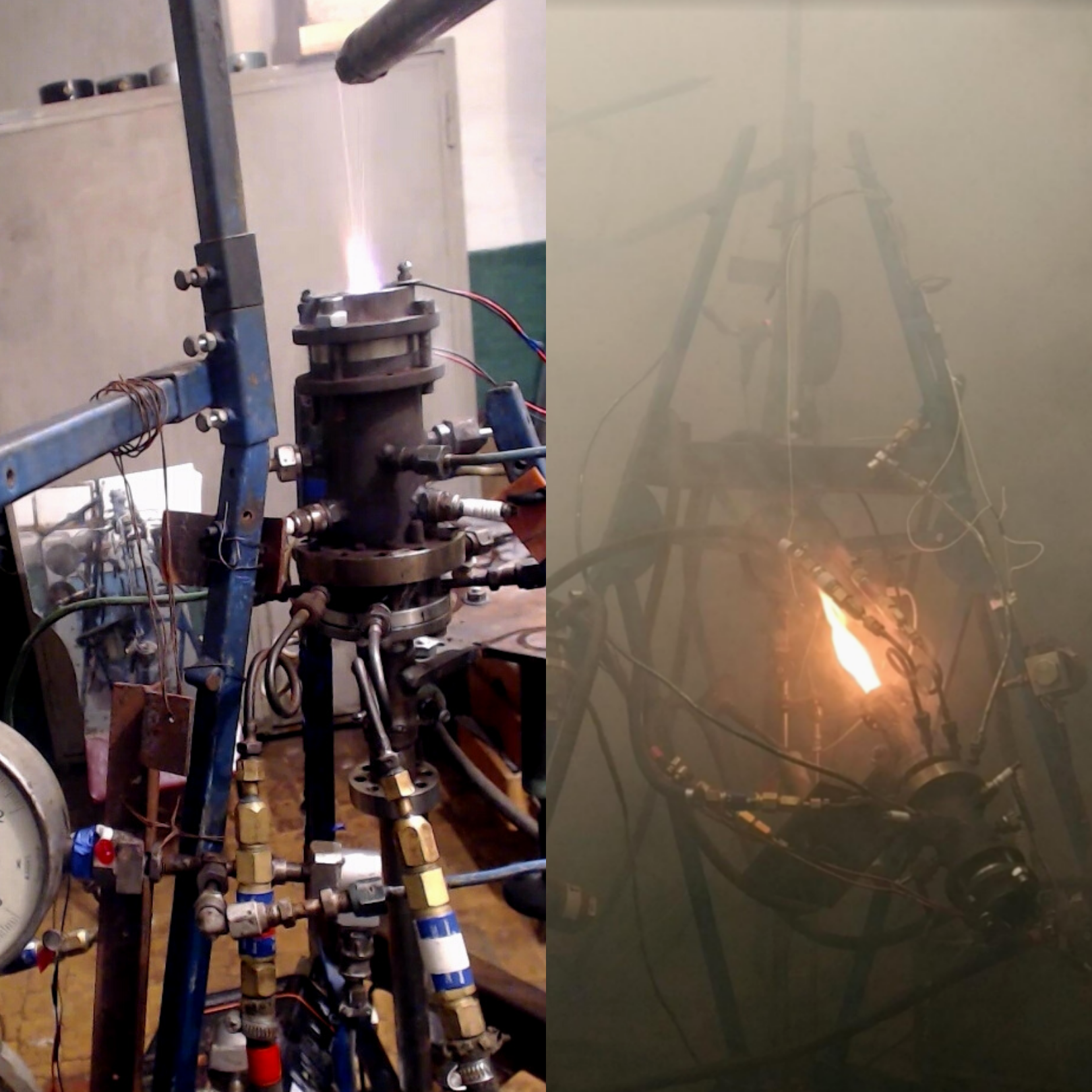

The very first test: an aerospike nozzle and a new gasifier

All through the new experiment, checks have been done on a new gasifier in which a stable gas rod is converted to fuel and fed to the engine. This gasifier was built using 3D printing.

The new gasifier improved the amount of polymer conversion to gas two to three situations as opposed to preceding tests performed with gasifiers produced using standard techniques. This was obtained owing to the greater region of gasification, the elaborate area obtained by laser printing.

The experiment lasted about 152 seconds. Fuel fuel was applied for the startup, and then strong fuel was stably fed to the gasifier working with an experimental motor. The feed rate was 6 to 8 millimeters for each second.

The engineers also conducted their very first test of an aerospike nozzle, which has a central entire body in the sort of a truncated cone inside of. The initially experiment gave a shocking result — extended stable combustion.

However, 93 seconds into the experiment, burnout in the combustion chamber was witnessed. The burnout transpired due to the deficiency of knowledge with a new modification of the gasifier and the aerospike nozzle. The engineers have by now formulated new methods to manage satisfactory motor temperatures for the future experiment.

The 2nd examination: a modified motor

The upcoming experiment the engineers carried out tested the enhanced modification of the motor. This time they set in multiple probes to monitor the temperature in a lot of motor areas to avoid burnouts, as experienced transpired in past fire assessments, and to have an understanding of the details of warmth move during testing. On top of that, comprehension the temperature subject of the latest modification supplies an necessary knowledge of the real procedures going on within the metal combustion chamber.

The propellant rod was fed into the gasifier, and firing parameters were recorded with several sensors. Combustion of the strong propellant rod, consisting of coaxial levels of oxidizers and polymer as a gas, was realized. The combustion efficiency remained steady for pretty much 50 seconds, with a measured feed charge of 1 millimeter per next.

Apparently, the disassembly and inspection following the examination exposed some unpredicted details. There was a small uncontrolled explosion in the course of the firing, whilst it did not result in the exam to be aborted.

In subsequent assessments, the starter gasoline was changed with a safer mixture to prevent this from happening.

Linked: The historical past of rockets

The 3rd test: a new oxidizer and a bell-shaped nozzle

Promin Aerospace’s engineers analyzed efficiency with a new oxidizer for the 3rd experiment on the improved motor. On top of that, a various, bell-shaped nozzle was connected and used. As with the former experiment, there were many probes monitoring the temperature in a lot of engine areas to recognize heat flow for the duration of tests and to aid stop burnout, as properly as pressure gauges in equally the combustion chamber and the pneumatic cylinder.

Next past experiments, the engineers fed the propellant rod into the gasifier when recording the firing parameters with multiple sensors. No troubles to realize combustion were discovered with the new oxidizer. Compared to the former experiment (which remained steady for almost 50 seconds, with a measured feed level of 1 mm/s), the combustion effectiveness was distinctly much more steady and successful the experiment remained stable for 268 seconds at a price of 7 mm/s.

The experiment ran for 277 seconds, including the preheating phase. However, at 268 seconds, an uncontrolled explosion caused the construction to be destroyed. Immediately after disassembly, it was clear that the cones of the gasifier had burned out, which could have triggered the oxidizer to turn into super-heated. Up until eventually that position in the experiment, the force and overall performance of the gas have been secure, suggesting that the new oxidizer is exceptionally effective.

For the following test, a gasifier handle will be used to make certain that the oxidizer does not turn out to be overheated. On top of that, a lot more precise temperature sensors will be used, and a gasoline-oxidizer barrier should be made to steer clear of destruction to the motor in an uncontrolled explosion. In general, in combination with the 3D printed gasifier, the oxidizer labored incredibly properly – it noticeably amplified the effectiveness.

As soon as all experiments on the engine have been done, Promin Aerospace programs to keep a suborbital trial launch this November and a commercial suborbital launch in early 2023. Promin Aerospace intends to start function on orbital launches right after concluding suborbital exams.

Promin Aerospace is based in Kyiv and Dnipro. Although Russia amplified its invasion in February, Promin Aerospace has been capable to continue on the growth of its autophagic rocket concept whilst its workforce juggle territorial defense.

“It is extremely important for providers with substantial-tech developments to carry on their work in the course of the war,” mentioned Volodymyr Taftay, the head of the State House Company of Ukraine. “They are the potential of our country and now aid its financial entrance.”

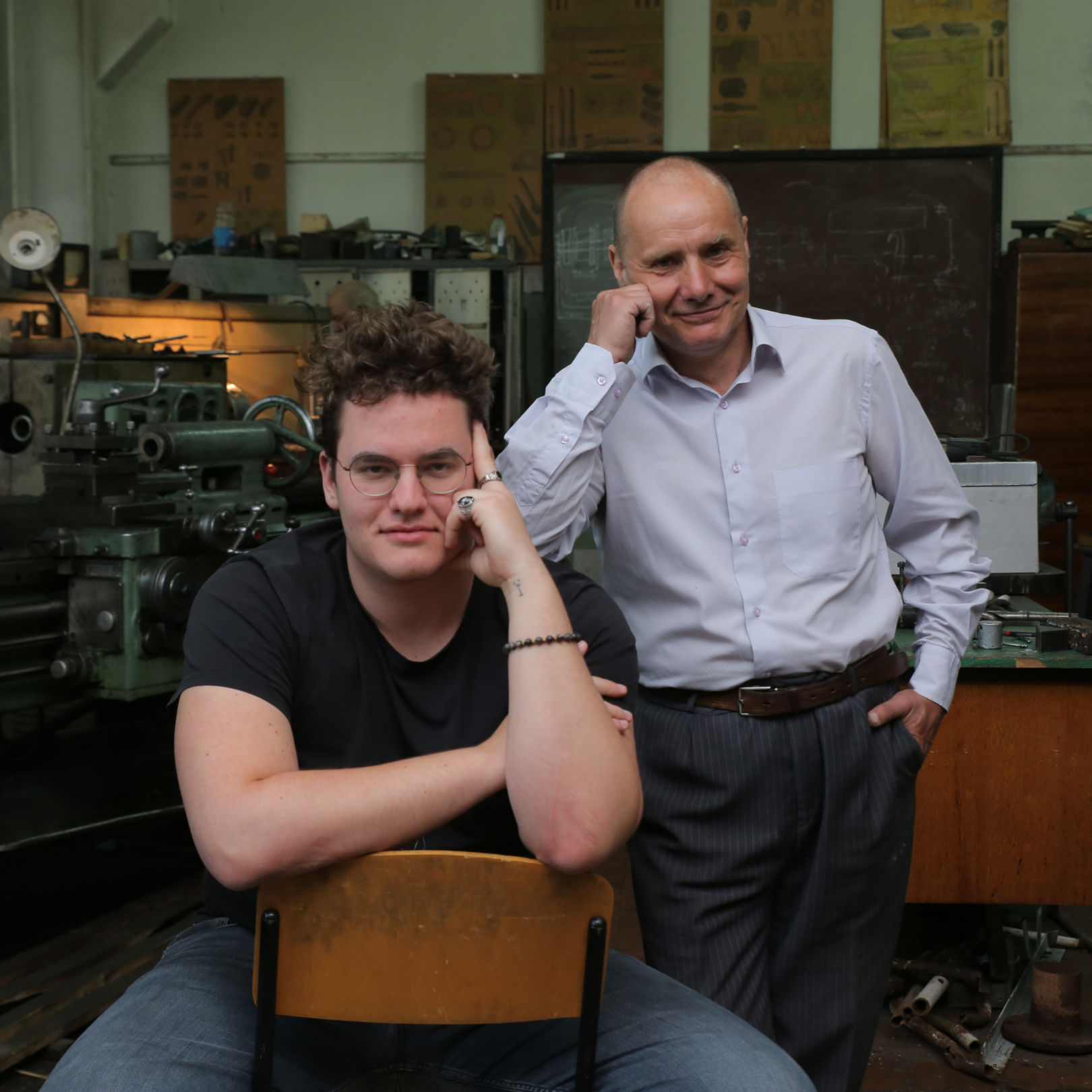

Promin Aerospace was recognized by Vitaliy Yemets and Misha Rudominski in 2021. It provides an totally new technological know-how for making start motor vehicles. This know-how will make private launches available for any business, minimizing their expense and preparation time when leaving no debris.

Comply with us on Twitter @Spacedotcom or on Facebook.